Article

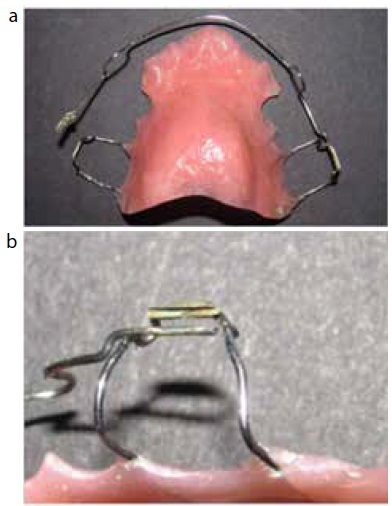

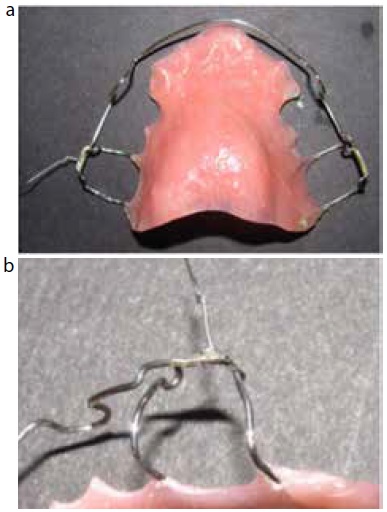

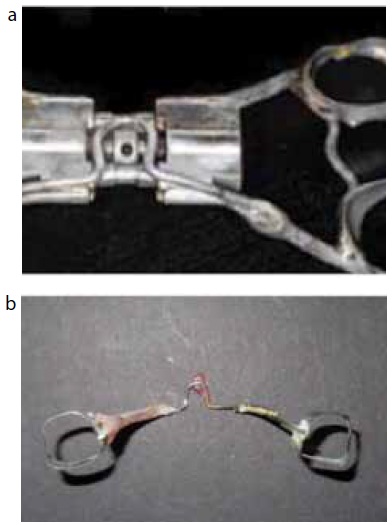

Soldering, to join wire components, and the placement of hooks and stops on archwires form an essential part of orthodontic practice (Figure 1). Though easy to perform, heating the wire component to high temperatures for a long duration results in the annealing of wire, which increases the appointment time and leads to frustration on the part of clinician and patient. This article showcases a technique to improve the soldering without annealing the wire component and suggests its application in clinical situations.

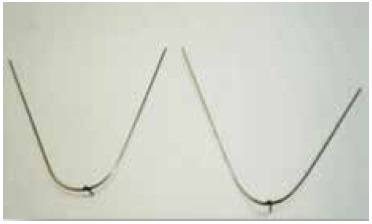

As against the norm of using the reducing zone (Figure 2) of the flame (blue zone), it is suggested that the non visible region (Figure 3) of the flame is used to achieve soldering. The blue zone avoids oxidation but the amount of heat generated is too great to achieve soldering without annealing the wire (Figure 4). However, the non visible region provides sufficient heat to achieve soldering.1

Clinical applications

Conversion of a rapid maxillary expander into transpalatal arch

After rapid maxillary expansion, it is common practice to secure the expansion screw and leave the appliance passively in place for several months. The clinician may then place a removable plate, a Hawley or Essix retainer, or a transpalatal arch (TPA) to maintain the transverse correction. Many authors2,3,4 have described techniques for converting a banded expander to a transpalatal arch; here is an alternative technique.

The final outcome is shown in Figure 5b.

Conversion can be performed chairside hence bypassing all laboratory work.

Repair of a fractured Hawley retainer

Patients often present with broken soldered wire components of removable appliances such as a Hawley retainer. It is difficult to stabilize wire components for soldering without models which would involve an additional impression. A simple technique to repair the broken components is presented: